Forged top-class Tools Hardened throughout

Optimal tool life and excellent breaking safety are the main features of our hydraulic chisels – even under the most difficult service conditions.

Through the use of heavy-duty steel, the very latest forging technology and a sophisticated hardening method, the hydraulic tools we produce acquire enormous fatigue strength, toughness and at the same time extremely high resistance to wear.

A number of factors determine the excellent quality of the hydraulic chisels.

Reliable with optimum utility value.

A particularly developed steel quality in connection with an environment-friendly hardening system

is the basis for through-hardened hydraulic chisels with optimal toughness.

Sophisticated forging technology brings the work piece into shape. The microstructure is bundled and provides:

a concentrated power transmission

a quick penetration

a long service life

a lower wear and tear on chuck and tool

The hardness of the standard chisel is adjusted to provide optimum coverage in more than 90% of applications. Decades of experience, a continuous dialogue with hammer manufacturers and users on locations, as well as up-to-the-minute production facilities provide solutions for your special tasks, such as chisels for industrial purposes, or usage in extremely soft or hard rock.

Four groups of digits form the ordering number for the tools:

70 Stands for the steel quality of SOLIDA hydraulic breaker tools

746 Describes the shank, suitable for hammer...

01 Indicates the design of the working side, in this case moil point

080 Designates the length of the tool, in this case 800 mm

| |

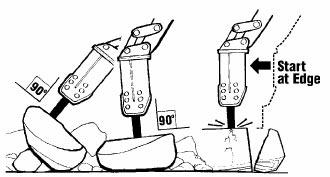

Correct use |

|

| |

|

|

|